How Sake Is Made

From polished rice to the glass — the traditional steps, equipment, and timing you’ll follow at home.

Get a Starter Kit

The Stages

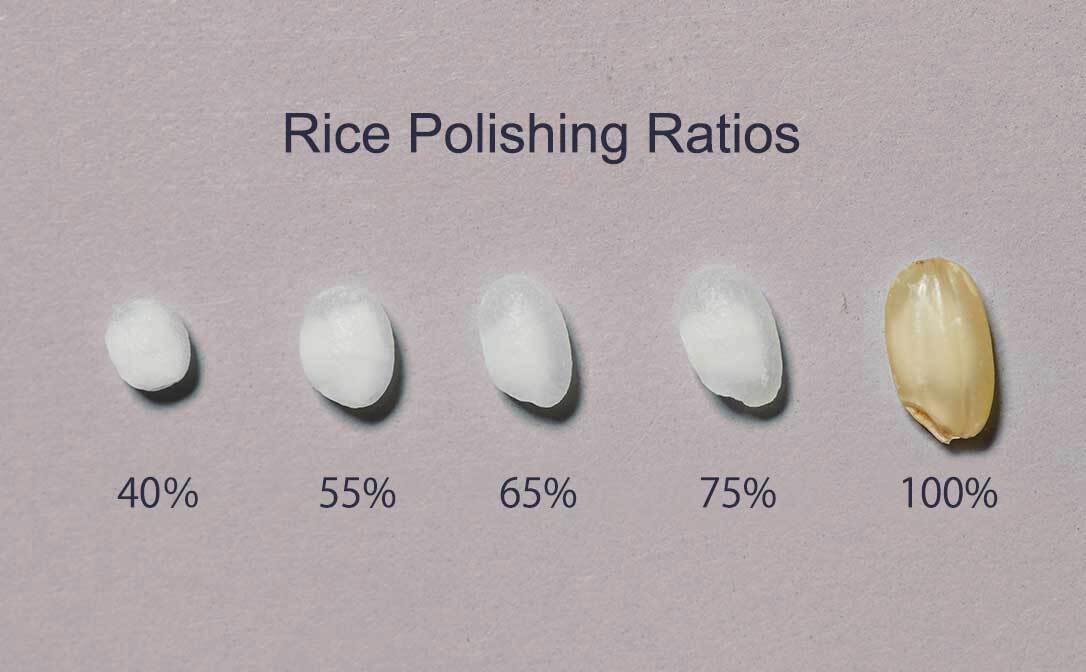

1) Rice Polishing

Rice is milled to remove outer layers (proteins/fats). Home brewers typically buy pre-polished rice.

2) Wash & Soak

Rinse until runoff is clear, then soak to a targeted absorption (~25–30%) before steaming.

3) Steam

Steam (not boil) to achieve a firm exterior and soft core — ideal for koji and fermentation.

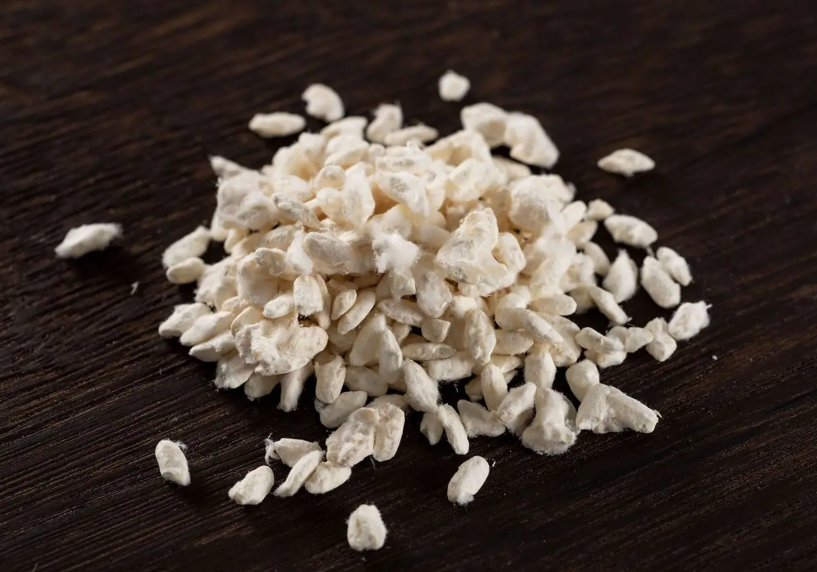

4) Koji

Inoculate a portion of steamed rice with A. oryzae. Koji enzymes convert starch into fermentable sugars.

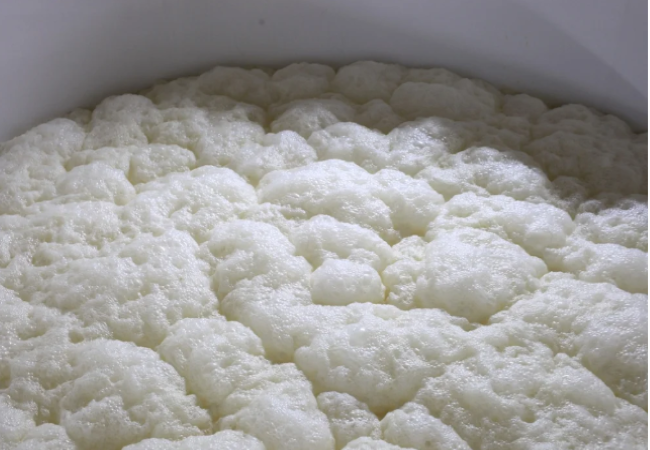

5) Shubo (Yeast Starter)

Build a strong yeast culture with koji, water, and a small rice portion for a clean fermentation.

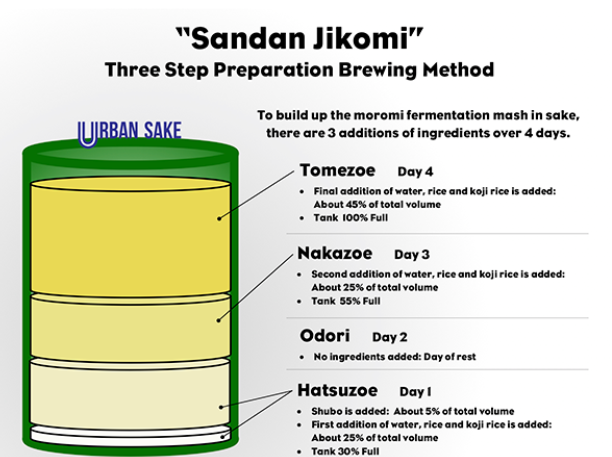

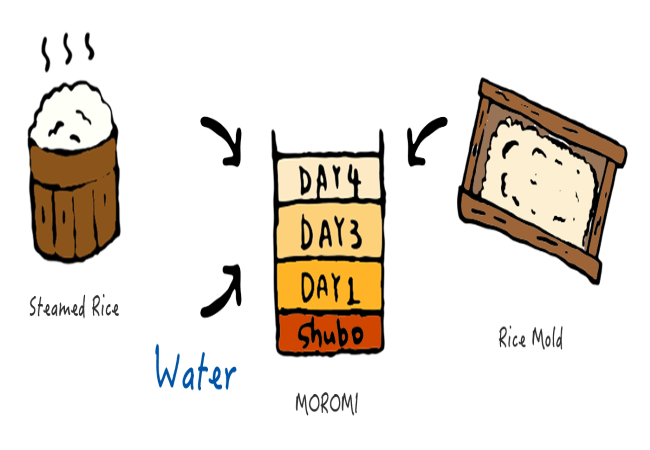

6) Moromi

Main mash built in three stages (sandan jikomi) over 4 days; fermentation 2–4 weeks at cool temps.

7) Press

Separate sake from lees (sake kasu) via press or bag drip. Then optionally fine & filter.

8) Stabilize

Many styles are pasteurized once or twice; some are left nama (unpasteurized; keep cold).

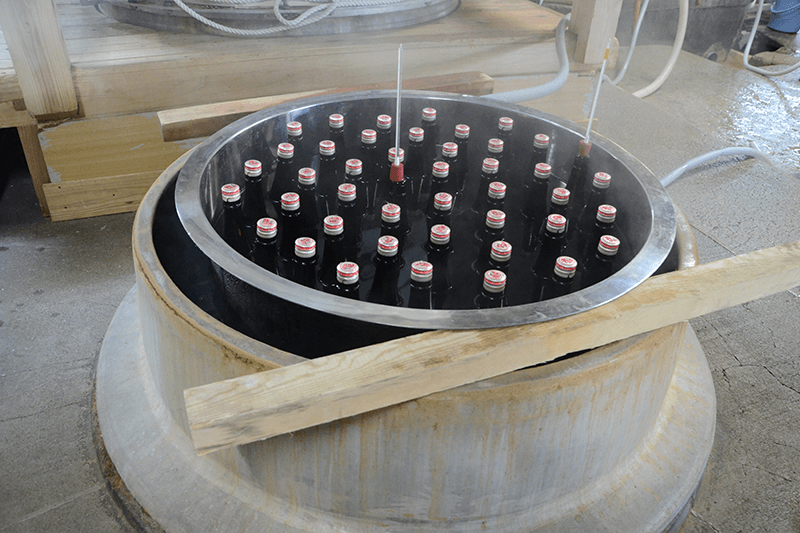

9) Bottle & Condition

Rest cold to round flavors; enjoy fresh or aged depending on style.

Equipment You’ll Use

- Food-grade fermenter (with airlock)

- Large steamer or steaming rig

- Koji tray/box & thermometer

- Sanitizer & spray bottle

- Fine straining bags / press

- Hydrometer or refractometer

- Siphon, bottles, caps

Detailed Walkthrough

Prepare & Sanitize

Clean gear is non-negotiable. Mix sanitizer and spray all contact surfaces.

Koji & Starter

Make koji from a portion of steamed rice; build a vigorous yeast starter (shubo).

Sandan Jikomi (Three-Stage Build)

Additions of rice/koji/water over 3 days grow the main mash (moromi) with excellent enzyme balance.

Ferment Cool & Monitor

Typical 8–15°C (46–59°F) for 2–4 weeks. Track gravity, aroma, and acidity.

Press, Stabilize, Bottle

Separate, optionally fine/filter, pasteurize if desired, then bottle and condition cold.